Coating Pan , Tablet Coating , Coating Process , Uniform Coating , Chocolate Coating #coatingpan

Call/Whatsapp :- +91-9099935528

Email Id :- info@multipackmachinery.com

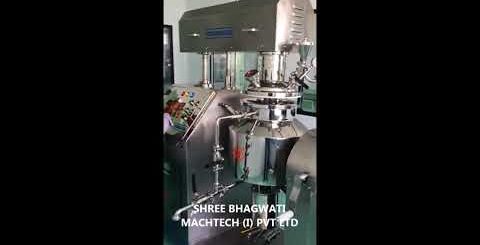

A coating pan, also known as a coating machine or coating drum, is a piece of equipment used in various industries for applying a coating or layer to solid materials, such as tablets, candies, nuts, pharmaceuticals, food products, and more. This process is often referred to as “coating” or “enrobing,” and it is used to enhance the appearance, taste, texture, or functionality of the products. Here’s a description of a typical coating pan:

1. Drum or Pan: The primary component of a coating pan is a large, cylindrical drum or pan. This drum is usually made of stainless steel, which is corrosion-resistant and easy to clean. The drum can vary in size depending on the application, ranging from small laboratory-sized pans to large industrial ones.

2. Rotation Mechanism: The drum is mounted horizontally on a rotating mechanism, allowing it to rotate about its axis. This rotation is essential for the coating process, as it ensures that the coating material is evenly distributed over the product.

3. Inlet and Outlet: There are openings in the drum for product and coating material to enter and exit. The product to be coated is introduced into the drum through the inlet, and the finished, coated product is discharged through the outlet.

4. Spraying System: A coating pan is equipped with a spraying system that dispenses the coating material onto the product. The coating material is often a liquid or melted substance, such as chocolate, sugar syrup, or a flavored solution. This system ensures an even distribution of the coating material across the product as the drum rotates.

5. Variable Speed Control: Many coating pans have variable speed control for the drum rotation. This feature allows operators to adjust the speed to achieve the desired coating thickness and quality. Slower rotation may be used for delicate products, while faster rotation is suitable for thicker coatings.

6. Air Handling: Some coating pans are equipped with air-handling systems to aid in drying or cooling the coated products. These systems can help to solidify the coating material and ensure a smooth finish.

7. Safety Features: Coating pans typically have safety features such as guards and interlocks to protect operators from moving parts and to ensure safe operation.

8. Cleaning and Maintenance: Easy cleaning and maintenance are essential aspects of coating pans, as they come into contact with various materials that need to be cleaned thoroughly to prevent cross-contamination. Many coating pans have removable parts for convenient cleaning.

Multipack delivers first class bottling machines, Shrink Sleeve Applicator, Shrink Wrapping machine, Shrink Tunnels, Auto Side Seal Machine , Stretch Wrapping Machine, BOPP/OPP Label Applicator, Cup Rinsing, Filling and Sealing Machine, Semi Auto/Fully Auto Container Sealing & Cutting Machine, Induction Wad Inserting Machine [cap lining machine], liquid filling machines, capping machines and labeling equipment for various size, shape and speed of bottles. All of Multipack unscrambling machines, filling machines, packaging machinery, capping machines, and labeling machines are manufactured in India and only uses reliable component brand names such as Festo, SMC, filler, Leuze ,Banner – Sunx – Sick sensor, Siemens, Delta – Mitsubishi PLC. This enables us to give competitive prices on all our services, while at the same time provide quality and reliable bottling equipment and packaging machines to our customer.

Multipack specialize in providing a complete turnkey solution, at very competitive prices, for all of your packaging machinery and bottling filling machine needs.

MULTIPACK Machinery Company ( MMC Group ) is a well-known World class manufacturing in packaging field, specializing in shrink sleeve packaging , Sleeving Machine, Shrink Labeller, Shrink Sleeve Applicator with worldwide selling with Premier Quality Equipment from Multipack brand , With More than 25 years of experience in packaging industry, we are able to deal with all kinds of containers in different size and shapes and material with 40 container per minute to 400 container per minute speed models . The Multipack Machines simplicity and elegance features of our machines design minimizes the possible of trouble and makes maintenance convenient. perform the functions there is always a solution to meet your need perfectly with smooth operation as well user friendly . These automatic end-of-line machines are able used in various industries such as Food and Beverages, Pharmaceuticals, Cosmetics, Personal Care Products, Electronics, Health Care, Agriculture, Pesticides, FMCG, Distribution, logistics, handling group Healthcare and biotech pharmaceutical, Herbal cosmetic, foodstuff and paper products to package them exactly as the customer requests.