V Blender, V Shape Blender #shreebhagwati

Make inquiry on aks@bhagwatipharma.com and contact us on +91 9099935527

@ShreeBhagwatiMachtechLimited @shreebhagwatimachtechindia9469 @BhagwatiMachtech

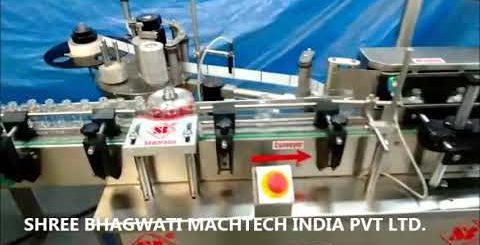

SHREE BHAGWATI MACHTECH (India) PVT. LTD.

Manufacturing Unit: 1

Plot No : 2802, Road No 4 E, Opp, Airway Surgical , Near Winflex ltd,

Ramol Cross Roads, G.I.D.C, Phase 4, Vatva, , Ahmedabad – 382445, Gujarat – India.

Manufacturing Unit: 2

Plot No. 5/22, Phase-1, G.I.D.C., Vatva, Ahmedabad – 382 445, Gujarat, India

Manufacturing Unit : 3

Plot No 708-P/18 Mukti Chokdi, Opp. GIL,G.I.D.C. Ankleshwar, Dist- Bharuch. Pin – 393002. Gujarat, India.

The V Blender, also known as the Y Blender, is a valuable piece of equipment in the pharmaceutical and food manufacturing sectors. Its popularity stems from its efficiency and short blending time, making it a widely used machine in the industry.The V Blender, also referred to as the twin shell blender, is constructed with two hollow cylindrical containers that are interconnected at an angle ranging from 75 to 90 degrees. The blending process of the V Blender involves continuous separation and recombination of the material while it tumbles, leading to a thorough mixing as it falls randomly in the vessel. This repeated motion of converging and diverging enhances the frictional contact between the material and the vessel, resulting in a gentle and uniform blend.This machine’s effectiveness makes it a go-to choice for manufacturing processes that require the precise mixing of different materials. The V Blender ensures that all components of the mixture are evenly distributed throughout the batch, leading to a consistent and high-quality product.The V Blender from Bhagwati Pharma Company offers unique advantages such as:

One of the key benefits of the V Blender is its ease of charging and discharging materials.

The machine is designed to ensure complete discharge of the product, which is not always the case with other blenders.

The V Blender also ensures there is no product contamination during the blending process.

The equipment is made of durable and long-lasting materials, providing a good return on investment for businesses that use it.