Tray Dryer , Tray Dryer machine , #dryer , electric hot air dryer

Call/Whatsapp :- +91 9099935527

Email I’d :- aks@bhagwatipharma.com

A vacuum tray dryer is a specialized piece of equipment used in various industries for drying sensitive or heat-sensitive materials, such as chemicals, pharmaceuticals, food products, and more. This type of dryer operates under reduced pressure or in a vacuum, which lowers the boiling point of water or other solvents, allowing for gentler drying at lower temperatures. Vacuum tray dryers are commonly used when traditional hot air drying methods are not suitable due to the risk of product degradation or combustion.

Here are some key features and components of a vacuum tray dryer:

1. Trays: The product to be dried is spread out in thin layers on trays within the dryer. These trays are usually made of stainless steel or other materials compatible with the specific drying process.

2. Vacuum System: A vacuum pump or system creates a reduced pressure environment within the dryer. This reduces the boiling point of liquids, allowing for faster and gentler drying at lower temperatures.

3. Heating System: Various heating methods can be used, such as electric heating elements, steam, or hot water, to provide the necessary heat for drying.

4. Cooling System: Some vacuum tray dryers have a cooling system to rapidly cool the dried product at the end of the process, preventing over-drying and maintaining product quality.

5. Control System: Modern vacuum tray dryers are equipped with sophisticated control systems that allow for precise monitoring and adjustment of temperature, pressure, and drying times.

6. Seals and Gaskets: Vacuum tray dryers must have airtight seals and gaskets to maintain the vacuum environment and prevent air from entering the drying chamber.

7. Safety Features: Safety features, such as pressure relief valves and emergency shutdown systems, are crucial to ensure the safety of operators and the equipment.

Vacuum tray dryers are commonly used in industries where product quality and consistency are of utmost importance, such as pharmaceuticals, food processing, and chemicals. They play a critical role in the production of products like powdered pharmaceuticals, herbs, spices, and various chemical compounds.

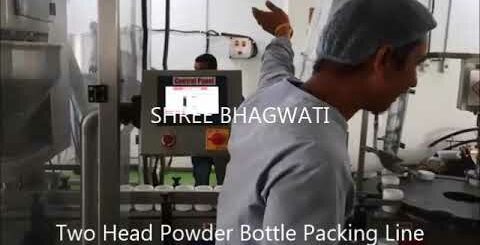

Shree Bhagwati Machtech India Private Limited provides complete solutions in Packaging Equipment’s and Materials. Our core Product range is Bottle Washing, Bottler Rinsing, Bottle Fillers, Bottle Capping, Bottle Labeling, Shrink Sleeve Applicators, Shrink Tunnel, Shrink Chambers, Shrink Wrapping Machines, Material Handling Equipment’s, Conveyors, Self Adhesive Sticker Labels and Printed Shrink Sleeves. We have supplied various machines for Talcum Powder Filling, Oil Filling, Adhesive Filling, Glue Filling, Gum Filling Lines, Milk Powder Filling Lines, Pharma Syrup Lines, Face Cream Filling Lines, Hair Oil Filling Lines, LIP Balm Line, Petroleum Jelly Filling Line, Cosmetic Filling Lines, Mineral Water Line, etc….

Our Machines are widely used in Pharma Syrup, Dry Syrup, Honey, Edible Oil, Lubricant Oil, Hair Oil, Shampoo, Phenol, Fruit Juice, Ready to Drink Juice, Cosmetics, Talcum Powder, Bleach Powder, Herbal Powder, Ayurveda Powder, Wine, Liquor, Electrical Components, Dental Products, Adhesive, Glue, Rubber Adhesive, Stationery, LIP Balm, Petroleum Jelly, Hair Developer, Hair Straightener, Hand Wash, Dish Wash, Hand Sanitizer, Cosmetic Lotion, Hair Wash, etc.

SHREE BHAGWATI MACHTECH (India) PVT. LTD.

Manufacturing Unit: 1

Plot No : 2802, Road No 4 E, Opp, Airway Surgical , Near Winflex ltd,

Ramol Cross Roads, G.I.D.C, Phase 4, Vatva, , Ahmedabad – 382445, Gujarat – India.

Manufacturing Unit: 2

Plot No. 5/22, Phase-1, G.I.D.C., Vatva, Ahmedabad – 382 445, Gujarat, India

Manufacturing Unit : 3

Plot No 708-P/18 Mukti Chokdi, Opp. GIL,G.I.D.C. Ankleshwar, Dist- Bharuch. Pin – 393002. Gujarat, India.

Follow us on

Facebook – https://www.facebook.com/bhagwatipharma/

Twitter – https://twitter.com/bhagwatipharma1

Pinterest – https://www.pinterest.com/bhagwatipharma/

Tumblr – https://bhagwatipharmacom.tumblr.com/

Instagram – https://www.instagram.com/shreebhagwatipharma/

#liquidfillingmachine

#bottlecapper

#bottlefiller

#bottling

#labeller

#packagingautomation

#bottlinglines

#packaginglines

#bottlefillingline

#bottlecappinglines

#bottlelabellinglines

#Stickerlabellingmachines

#Bottlecappingmachines

#Bottlefillingmachines

#toiletcleanerfillingmachines

#disinfectantliquidfillingmachines

#creamfillingmachines

#edibleoilfillingmachines

#VacuumTrayDryer

#DryingTechnology

#HeatSensitiveMaterials

#IndustrialDrying

#Pharmaceuticals

#ChemicalIndustry

#FoodProcessing

#ProductQuality

#EnergyEfficiency

#ControlSystems

#SafetyFeatures

#Manufacturing

#QualityControl

#Engineering

#Innovation

#ProductDrying

#ProcessingEquipment

#GentleDrying

#VacuumTechnology

#DryingSolutions